Kis türelmet...

Kis türelmet...

1. Introduction

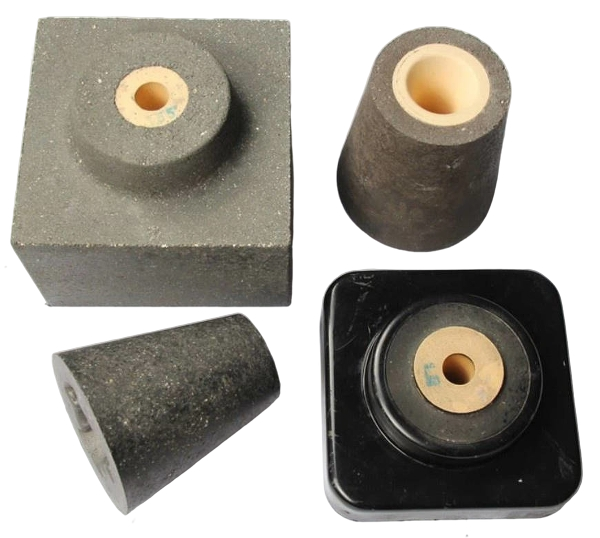

Thetundish metering nozzle is a critical refractory component in continuous casting, serving as the final flow-control element between the tundish and the mold or submerged entry nozzle. Its performance directly influences casting stability, steel cleanliness, surface quality, productivity, and operational safety. Despite continuous improvements in refractory materials and casting technology, tundish metering nozzles remain vulnerable to a range of operational, metallurgical, thermal, and mechanical problems.

Failures or degradation of tundish metering nozzles can lead to unstable mold levels, inclusion entrapment, strand breakouts, emergency shutdowns, and even serious safety incidents involving molten steel leakage. This article provides a comprehensive analysis of the major problems associated with tundish metering nozzles, including their root causes, mechanisms, and consequences, with a focus on practical casting operations.

2. Nozzle Clogging and Flow Restriction2.1 Inclusion-Induced Clogging

One of the most common and costly problems in tundish metering nozzles is clogging caused by non-metallic inclusions. During continuous casting, inclusions such as alumina (Al₂O₃), spinel (MgAl₂O₄), calcium aluminates, or complex oxide clusters can deposit on the inner surface of the nozzle bore.

Key mechanisms include:

Adhesion of solid inclusions to refractory surfaces

Agglomeration of fine inclusions into larger clusters

Growth of inclusion layers due to continuous deposition

As clogging progresses, the effective flow area of the nozzle decreases, leading to:

Reduced casting speed

Unstable mold level

Increased reliance on slide-gate or stopper-rod adjustments

Sudden flow interruptions

Severe clogging may require premature tundish change or emergency casting termination, resulting in productivity losses and increased refractory consumption.

2.2 Chemical Reactions at the Nozzle Wall

Chemical interactions between molten steel, inclusions, and refractory phases can exacerbate clog formation. For example, alumina-based refractories may react with dissolved calcium or magnesium in the steel, forming complex oxides with higher melting points that readily adhere to the nozzle wall. Over time, these reaction products form a rigid clog structure that is difficult to remove during casting.

3. Thermal Freezing and Solidification3.1 Insufficient Preheating

Thermal freezing occurs when molten steel solidifies partially or completely within the nozzle bore. This problem is frequently associated with inadequate preheating prior to casting start-up.

Contributing factors include:

Cold nozzle surfaces absorbing heat from the steel

Short ladle change delays causing temperature drop

Low superheat steel grades

Even small frozen steel shells can dramatically restrict flow and act as nucleation sites for inclusion attachment, accelerating clog development.

3.2 Heat Loss During Casting Interruptions

Unplanned casting pauses or speed reductions allow heat loss from the nozzle, particularly at the outlet region. This can result in localized solidification, causing partial blockage that destabilizes flow upon restart.

4. Erosion and Wear of the Nozzle Bore4.1 Mechanical Erosion by Steel Flow

High-velocity molten steel flowing through the nozzle causes mechanical erosion of the refractory material. This effect is intensified by:

High casting speeds

Turbulent flow regimes

Abrasive inclusions entrained in the steel

Erosion gradually enlarges the nozzle bore, leading to increased flow rates that are difficult to control and may exceed design limits for mold level stability.

4.2 Chemical Corrosion by Slag and Steel

Chemical corrosion occurs when slag components or steel alloying elements react with the refractory phases of the nozzle. Alkali oxides, calcium oxide, and iron oxides can dissolve or weaken alumina- or magnesia-based refractories, leading to:

Pitting and localized thinning

Accelerated wear at the slag–metal interface

Reduced structural integrity

5. Air Aspiration and Oxidation5.1 Leakage at Nozzle Interfaces

Air aspiration occurs when gaps or cracks allow atmospheric air to enter the steel stream through the nozzle assembly. Common causes include:

Poor installation or misalignment

Cracked refractory components

Inadequate ramming or sealing material

Air ingress introduces oxygen and nitrogen into the molten steel, promoting:

Reoxidation and formation of new inclusions

Increased clogging potential

Degradation of steel cleanliness

5.2 Consequences of Reoxidation

Reoxidation at the nozzle accelerates inclusion formation directly at the flow restriction point, creating a feedback loop where newly formed inclusions contribute to further clogging and flow instability.

6. Misalignment and Mechanical Damage6.1 Installation-Related Problems

Improper alignment of the tundish metering nozzle during installation can significantly shorten service life. Even minor angular deviation can cause:

Uneven flow distribution

Asymmetric wear of the bore

Localized thermal stress

Misalignment also increases the risk of steel leakage at the nozzle–well block interface.

6.2 Mechanical Impact and Handling Damage

Nozzles are susceptible to cracking or chipping during transportation, storage, or installation. Hidden microcracks may propagate under thermal stress during casting, leading to sudden failure.

7. Steel Leakage and Safety Risks7.1 Refractory Cracking and Breakout

One of the most dangerous problems associated with tundish metering nozzles is molten steel leakage. Cracks or erosion pathways can allow steel to penetrate the nozzle body and escape externally.

Potential consequences include:

Damage to tundish structure

Risk of fire or explosion

Severe safety hazards to personnel

Emergency shutdowns and long downtime

7.2 Progressive Leakage Mechanism

Leakage often begins as minor seepage, which can be difficult to detect. If not addressed promptly, the leakage path enlarges, leading to catastrophic failure.

8. Interaction with Flow Control Devices8.1 Slide Gate Plate Problems

When used in combination with slide gate systems, tundish metering nozzles can suffer from:

Uneven plate wear due to flow turbulence

Localized overheating

Increased friction and mechanical stress

Poor compatibility between nozzle material and gate plate material can worsen sealing performance and accelerate wear.

8.2 Stopper Rod Interaction

In stopper-rod systems, improper seating between the stopper tip and nozzle bore can cause:

Eccentric flow

Accelerated local erosion

Reduced flow control precision

9. Operational and Economic Consequences

The cumulative effect of tundish metering nozzle problems includes:

Reduced casting sequence length

Increased refractory consumption

Higher maintenance and labor costs

Increased defect rates in finished steel

Lower overall plant productivity

Even small improvements in nozzle reliability can translate into significant cost savings at high-throughput casting operations.

10. Mitigation Strategies and Preventive Measures

Although this article focuses on problems, understanding them enables targeted countermeasures, such as:

Improved steel cleanliness upstream

Optimized nozzle materials and insert designs

Proper preheating and thermal management

Controlled argon purging

Precise installation and alignment procedures

Real-time monitoring of pressure and flow behavior

A holistic approach combining metallurgical control, refractory engineering, and operational discipline is required to minimize nozzle-related issues.

11. Conclusion

Tundish metering nozzles operate under some of the most demanding conditions in the steelmaking process. They are exposed to extreme temperatures, aggressive chemical environments, high-velocity molten steel, and complex inclusion dynamics. As a result, a wide range of problems — including clogging, erosion, thermal freezing, air aspiration, misalignment, and leakage — can occur during service.

Understanding these problems in depth is essential for engineers, operators, and refractory specialists seeking to improve continuous casting performance. While no nozzle is entirely problem-free, advances in material technology, improved installation practices, and better process control continue to reduce failure rates and extend service life. Ultimately, effective management of tundish metering nozzle problems is a cornerstone of stable, safe, and high-quality continuous casting operations.

Functional Refractory Items In The Tundish

How To Protect The Liquid Steel From Oxidation

E-mail: ugyfelszolgalat@network.hu

Kommentáld!